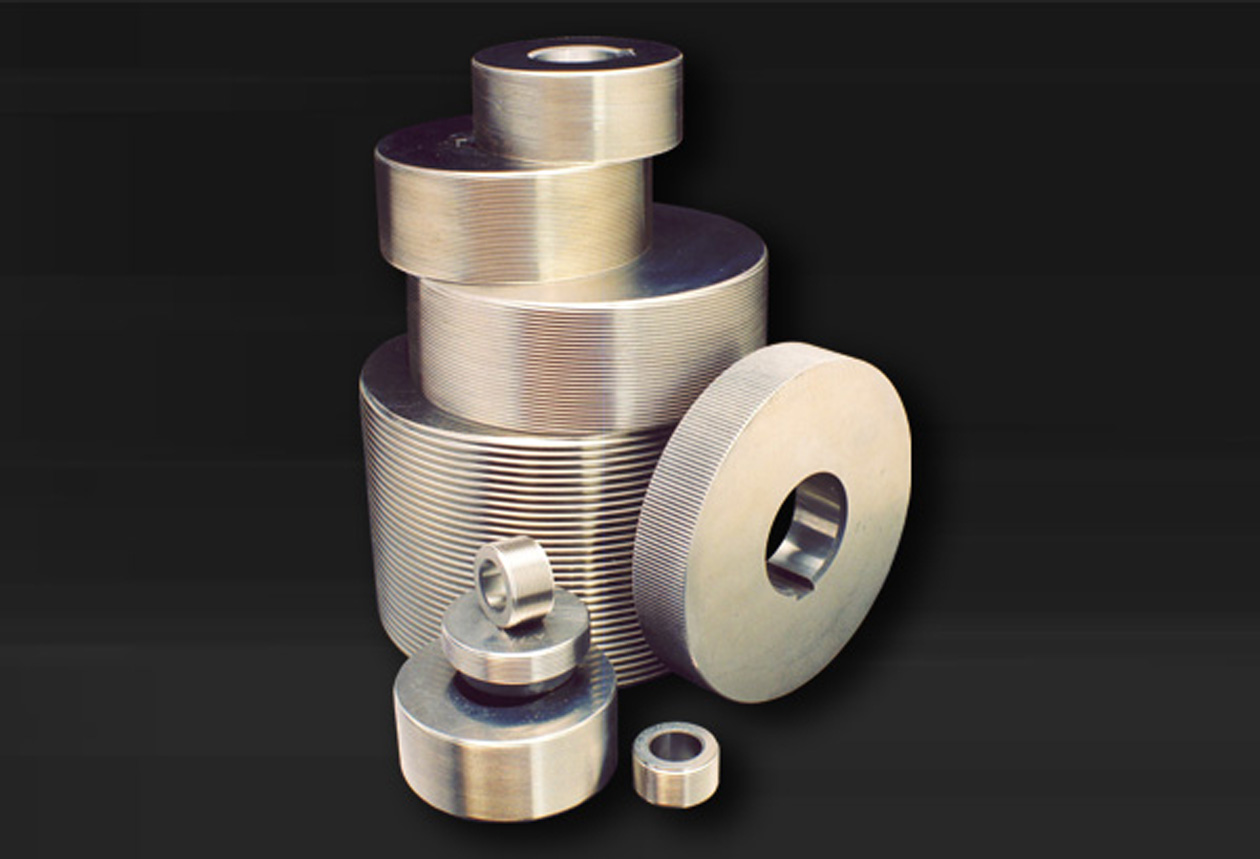

Thread Rolls

- Rolls For Multi Start Jobs.

- Infeed Rolls.

- Annular Through Feed Rolls ( with or without Lead - In)

- Helical Through Feed Rolls (With Lead In & Run Off)

- Rolls for Fette Heads/ Winter Heads/Wagner Heads

- Rolls For Other Tangential Heads

- Rolls For Making Oil Grooves.

| THREAD PROFILE | ANGLE |

| Metric | 60 |

| British Standard Withworth | 55 |

| British Standard Fine (BSF) | 55 |

| British Association (BA) | 47.5 |

| American Standard ACME | 29 |

| American Standard Butttress | as per customer Requirement |

| Unified (UNC/ UNF / UNEF ) | 60 |

| National Pipe Taper (NPT) | 60 |

| National Pipe Straight (NPS) | 60 |

Any special thread profile as per customer's requirements can also be made upto Ø 300mm.

| STEELS USED IN MANUFACTURER OF THREAD ROLLS | |||

| Steel | APPLICATION | HARDNESS OF ROLL | |

| AISI D2 | USED FOR COMPONENTS UPTO 16HRc | 59 - 61 HRc | |

| DELTA STEEL | USED FOR STAINLESS STEEL (EXCEPT 202) AND HARDEND COMPONENT ROLLING UPTO 32 HRc | 61 - 63 HRc | |

| DM5 | USED FOR STAINLESS STEEL (EXCEPT 202) AND HARDEND COMPONENT ROLLING BETWEEN 30 - 45HRc | 61 - 64 HRc | |

| HSS M2 | USED FOR STAINLESS STEEL (EXCEPT 202) AND HARDEND COMPONENT ROLLING BETWEEN 30 - 45HRc | 62 - 64 HRc | |

| HSS M35 | FOR TANGENTIAL ROLLING HEAD ROLLS | 62 - 64 HRc | |

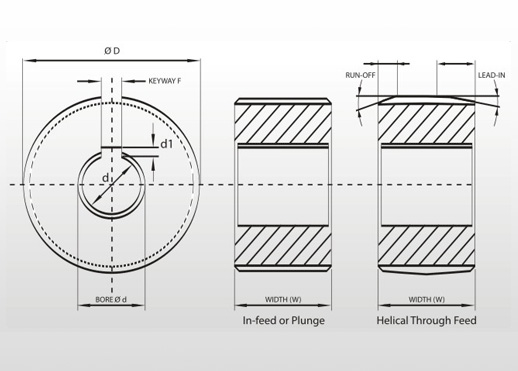

| Keyway (C11) |

|||

| Bore Diameter d (H7) | Width F | Depth d1 | Width of Thread Roll (W) |

| 40 | 12 | 4 | From 30 mm to 180 mm |

| 54 | 12 | 4 | |

| 63 | 12 | 4 | |

| 69.85 | 12.7 | 5 | |

| 80 | 16 | 5 | |

| 100 | 16 | 5 | |

| Type of Machine | Max. Dia. of Thread Roll in mm. | Recomended Max. Width of Roll in mm. |

| Praga 511 | 100 | 50 |

| WMW 8 ton | 125 | 80 |

| Baco Smith | 130 | 80 |

| Praga 512 | 170 | 130 |

| MTR - 15 170 | 130 | 130 |

| WMW 12.5 Ton | 185 | 150 |

| Praga 513 | 200 | 150 |

| Praga 514 | 230 | 150 |

| WMW 25 Ton | 230 | 180 |